What Digital Access Control Can Learn from Value Engineering

11th March 2025 | by Karsten Nölling (KIWI CEO)

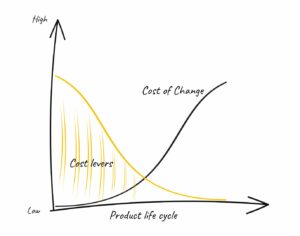

Value Engineering is a simple yet powerful concept I first encountered during my early career at Mercedes-Benz, where we applied Toyota’s Lean Manufacturing methods to drive cost reduction. The core principle is straightforward: the majority of a product’s costs are determined during its design and engineering phase. As you move further downstream—through manufacturing, assembly, and distribution—the ability to significantly reduce costs diminishes, even though optimization is still possible.

The Value Engineering Lifecycle in Access Control

This concept also has profound implications for digital access control when applied to the entire lifecycle of a product. While components such as knobs, readers, and PCBs will continue to play an important role, they are becoming increasingly commoditized, particularly with global manufacturing quality and competencies increasing (think China). The real „design and engineering“ phase of access control now clearly resides in software development (with a close link to firmware and hardware design of course). Software is where the costs and efficiencies (and user experience) for all downstream activities throughout the life cycle of a digital access point are determined.

Consider the various stakeholders involved in digital access and how their costs and product experience are shaped by software design decisions:

- Distributors & Installers: How easily can they deploy and configure systems?

- Administrators: How intuitive is the process of managing (large amounts) of users, doors and changing access permissions across multiple sites?

- End users: how easy is the process of managing (small amounts) of users, doors and permissions? And how intuitive is the actual door opening?

Each of these steps can be designed to be seamless and error-free- or cumbersome, costly, and prone to human mistakes. The choice is made at the very beginning , in software architecture and UI/UX design.

Learning from Automotive Manufacturing

Just as in the automotive industry, if a design engineer fails to understand the complexities of manufacturing—such as how body parts are forged—the production process becomes unnecessarily expensive and inefficient. No amount of downstream process optimization can ever compensate for poor design decisions made early on.

The same principle applies to digital door access. If product designers and software engineers don’t deeply understand how their systems will be used by real people in the field on a daily basis, the result will be clunky, inefficient, and frustrating to use. Without visibility into these real-world interactions, even the most well-intentioned products can fail to deliver value.

The Future of Digital Access Control: Eat your own dog food along the entire value chain

The days of access control companies shipping hardware without knowing where or how it will be used will not come to an end, but the role of manufacturers will be reduced to providing hardware commodity products with relatively low margins – unless they really get into the software side of things. The companies that will lead the future are those that understand, in granular detail, every step that B2B2C stakeholders take throughout the lifecycle of a door and its digital access use case. Arguably, the large distributors (aka channels aka system integrators aka what-should-we-call-them) are better positioned as they are closest to their customers. Either way, the companies that “eat their own dog food” on a daily basis and are able to build the right software for the right use case and forever improve in fast step by step iterations based on the daily learnings will take a much bigger piece of the growing digital door access market.

And a clarifying note on “eating your own dog food“: there is a common misconception in many product teams that interviewing or observing customers using your product is providing sufficient insights for product development. Far from it. While interviewing, shadowing, observing etc. your customers or internal front line teams on how they interact with your product are useful and important tools, they are by no means sufficient. To expand on the dog food analogy: it sure is helpful to analyze your dog food or observe others eating it. Rest assured that nothing will create faster improvements to your product than eating your dog food every day – I would argue at least by a factor of 10.

So coming back to value engineering: More than anything else in digital access, software has the power to shape both the cost curve and the overall user experience (which can also be thought of as an “experience happiness curve”, very similar to the value engineering cost curve).

By applying value engineering principles to access control—focusing on early-stage design and engineering with a deep understanding of downstream processes and use cases—companies can drive down costs, improve efficiency, and create seamless and superior product experiences for everyone involved.